Suspension Maintenance: The Ultimate Guide to a Smoother, Safer Ride

Learn everything about maintaining your vehicle's suspension system - from recognizing warning signs to preventative maintenance. Discover when to replace vital components and how proper suspension care enhances safety, comfort, and vehicle longevity.

Your vehicle's suspension system is the unsung hero of your driving experience. It absorbs bumps, maintains tire contact with the road, and ensures handling stability. Yet many drivers overlook this critical system until something goes wrong. This comprehensive guide covers everything you need to know about maintaining your suspension to extend vehicle life, improve safety, and enjoy a more comfortable ride.

Understanding Your Suspension System

Your vehicle's suspension is a complex system of components working together to provide a smooth ride while maintaining control. The main components include:

Shock Absorbers

These hydraulic devices dampen the movement of your springs, preventing your vehicle from bouncing excessively after hitting bumps. They convert kinetic energy into heat energy, which dissipates through the hydraulic fluid.

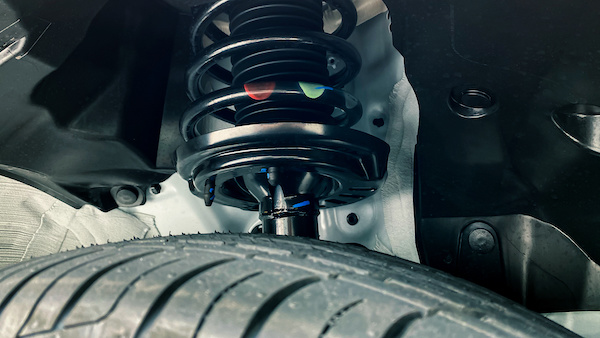

Struts

Struts combine the functions of shock absorbers and structural support. They are load-bearing components that also provide damping functions. Many modern vehicles use struts on the front suspension and shocks on the rear.

Springs

Coil springs, leaf springs, or torsion bars absorb impacts from road irregularities and support the vehicle's weight. They store energy when compressed and release it when extended, which is why proper damping from shocks is essential.

Control Arms and Bushings

These components connect your suspension to the vehicle's frame, allowing for controlled movement while isolating vibration. Bushings are rubber or polyurethane components that reduce noise and harshness while allowing necessary movement.

Ball Joints

These spherical bearings connect your control arms to the steering knuckles, allowing for pivoting movement while maintaining strength. They're critical for proper steering and suspension operation.

Warning Signs of Suspension Problems

Your vehicle will usually tell you when suspension components are wearing out. Here are the key warning signs to watch for:

- Excessive Bouncing

If your vehicle continues to bounce more than once or twice after hitting a bump, your shocks or struts may be worn out.

- Nose Diving When Braking

If your vehicle dips forward dramatically when braking, your front suspension is likely worn.

- Uneven Tire Wear

While often a sign of alignment issues, uneven tire wear can also indicate worn suspension components.

- Knocking or Clunking Noises

Unusual sounds when driving over bumps often indicate worn ball joints, control arm bushings, or strut mounts.

- Vehicle Pulling to One Side

While this can be an alignment issue, it can also indicate uneven suspension wear or damage.

- Oily or Wet Shocks/Struts

Visual inspection revealing fluid on the outside of shocks or struts indicates seal failure and need for replacement.

Safety Warning: Don't ignore these warning signs. Suspension problems can lead to unpredictable handling and increased stopping distances, significantly increasing your risk of accidents.

Preventative Suspension Maintenance

While suspension components will eventually wear out, proper preventative maintenance can significantly extend their lifespan and improve your vehicle's performance:

Regular Inspections

Have your suspension inspected during routine oil changes or every 12,000-15,000 miles. A professional can spot early signs of wear before they become major issues.

Keep It Clean

Dirt and road salt can accelerate wear on suspension components. Regular underbody washing, especially in winter months or after off-road driving, can prevent premature corrosion.

Maintain Proper Alignment

Misalignment puts extra stress on suspension components. Regular wheel alignments help extend the life of tires and suspension parts while improving handling and safety.

Address Small Issues Promptly

Don't ignore minor noises or handling quirks. Small issues can quickly escalate into major problems, and early intervention is typically less expensive than waiting until components fail completely.

Consider Your Driving Habits

If you frequently drive on rough roads or carry heavy loads, consider upgrading to heavy-duty suspension components designed for more demanding conditions.

Pro Tip: Pay attention to how your vehicle feels after driving over bumps. A properly functioning suspension should absorb the impact and settle quickly without continued bouncing or swaying.

When to Replace Suspension Components

Even with proper maintenance, suspension components have a finite lifespan. Here's a general guideline for replacement intervals:

Shock Absorbers and Struts

Typically need replacement every 50,000-100,000 miles, depending on driving conditions and vehicle type. Performance degrades gradually, so many drivers don't notice until function is significantly impaired.

Ball Joints

Generally last 70,000-150,000 miles, but can fail sooner with rough driving conditions. Ball joints are critical safety components - failed ball joints can cause catastrophic steering loss.

Control Arm Bushings

Bushings typically last 60,000-100,000 miles. Rubber deteriorates over time, even without high mileage. Polyurethane bushings last longer but may provide a stiffer ride.

Springs

Springs can last the lifetime of the vehicle in ideal conditions, but may sag or break after 100,000+ miles, especially in areas with salted roads or after frequent exposure to large impacts.

Pro Tip: When replacing suspension components, always replace in pairs (both front shocks, both rear struts, etc.) even if only one appears worn. This maintains balanced handling and prevents uneven wear.

DIY vs. Professional Suspension Work

What You Can DIY

- Visual Inspections

Checking for leaks, damage, or unusual wear can be done at home

- Bounce Test

Push down on each corner of your vehicle and release. It should bounce once and settle quickly

- Some Bushing Replacements

With proper tools and mechanical knowledge, some bushings can be replaced at home

When to Seek Professional Help

- Strut/Shock Replacement

Requires specialized tools and safety precautions due to compressed springs

- Ball Joint Replacement

Critical safety component that requires precision installation and specialized tools

- Alignment Services

Requires specialized equipment to measure and adjust suspension angles properly

Safety Warning: Never work under a vehicle supported only by a jack. Always use proper jack stands and follow safety procedures. Coil springs store tremendous energy and can cause serious injury if mishandled.

Understanding Suspension Repair Costs

Suspension repair costs vary widely based on vehicle make, model, and the specific components being replaced. Here's a general pricing guide to help you budget appropriately:

Basic Maintenance

$100-$300 for inspections, lubrication of components, and minor adjustments

Moderate Repairs

$300-$800 for replacement of individual components like shocks, struts, ball joints, or control arm bushings

Major Overhaul

$1,000-$5,000+ for complete suspension rebuilds, replacement of multiple components, or luxury/specialty vehicle work

Remember: While suspension work isn't cheap, neglecting needed repairs can lead to more expensive damage, premature tire wear, and compromised safety. Consider it an investment in your vehicle's longevity and your personal safety.

Key Takeaways for Suspension Maintenance

A well-maintained suspension system is essential for safety, comfort, and vehicle longevity. By understanding your suspension components and recognizing early warning signs, you can address issues before they become critical or expensive.

- Schedule regular inspections

Include suspension checks as part of your routine maintenance schedule

- Pay attention to warning signs

Don't ignore unusual noises, vibrations, or handling changes

- Choose the right components for your needs

Consider driving habits when choosing replacement parts - performance, comfort, or durability

- Invest in quality

Quality parts generally offer better value than the cheapest options

- Always align after suspension work

Get post-suspension work alignment to ensure optimal tire wear and handling

Remember that your suspension system affects nearly every aspect of your driving experience, from comfort and handling to safety and fuel efficiency. Taking care of it properly isn't just good maintenance—it's essential for safe driving.

Suspension Maintenance Quick Tips

- Perform a visual check of shock absorbers and struts for leaks or damage monthly

- Listen for unusual sounds when driving over bumps or railroad tracks

- Check tire wear patterns for signs of suspension issues

- Keep your vehicle's weight within manufacturer recommendations

- Consider upgrading to better quality components when replacements are needed

- Address suspension issues before they affect other systems like steering and brakes

Big on Fast. Big on Friendly.

Don't wait until you notice warning signs. Our certified technicians at Big Brand Tire & Service are here to help keep your vehicle running at its best!